Transforming asset reliability with Experion’s engineering excellence and AI-driven intelligence

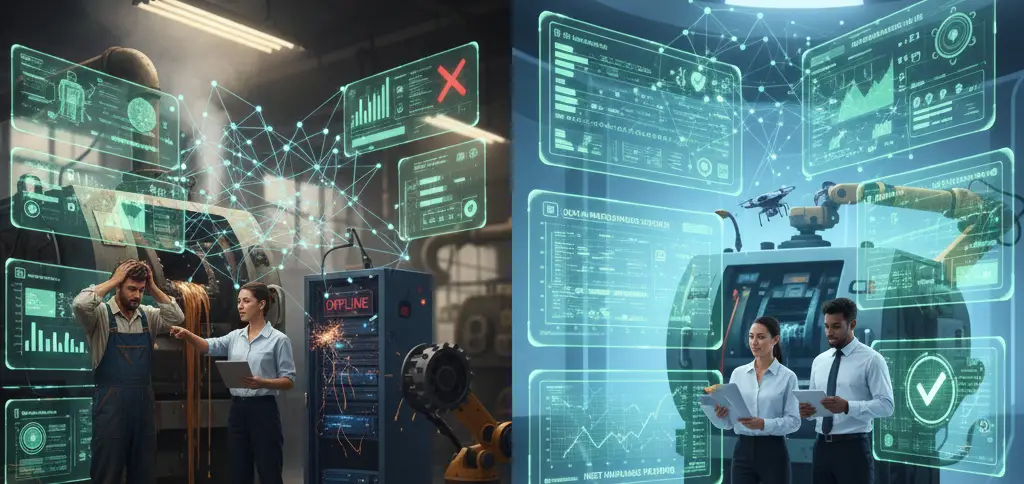

Organizations across industries are shifting from traditional maintenance approaches toward intelligent prediction and automation. AI predictive maintenance has emerged as one of the most impactful applications of artificial intelligence in operations-heavy sectors, enabling companies to detect failures early, prevent costly breakdowns, and optimize asset performance. As businesses seek more predictable, efficient, and data-driven operations, AI predictive maintenance software is becoming the strategic backbone of modern digital transformation.

Conventional maintenance methods, whether reactive or preventive, often result in unplanned downtime, excessive repairs, unnecessary maintenance cycles, and rising operational costs. AI predictive maintenance changes this entirely. By combining machine learning, AI prediction algorithms, IoT sensors, and real-time analytics, businesses gain the ability to continuously assess equipment health, identify anomalies, predict failures before they occur, and take timely action.

This shift toward AI based predictive maintenance is accelerating across manufacturing, energy, oil and gas, logistics, transportation, healthcare, and smart infrastructure. As organizations adopt AI predictive models and intelligent monitoring systems, the future of maintenance is moving toward autonomous decision-making, self-healing assets, and AI-powered predictive maintenance workflows.

What Is AI Predictive Maintenance?

AI predictive maintenance refers to the use of artificial intelligence, machine learning, and sensor-driven data to forecast equipment failures before they happen. Instead of relying on fixed schedules or waiting for machines to break, AI for predictive maintenance continuously analyzes data patterns, assesses asset degradation, and provides early warnings so maintenance can be planned at the optimal time.

AI in predictive maintenance differs significantly from older approaches because it does not rely solely on historical averages or manual inspections. Instead, it uses AI prediction models and advanced algorithms to understand real-time asset behavior, detect anomalies instantly, and estimate remaining useful life (RUL). This capability makes AI predictive maintenance software far more accurate, cost-efficient, and scalable than traditional condition monitoring.

Why Predictive Maintenance Matters Today?

Rising Equipment Complexity and Downtime Costs

Modern industrial equipment is more complex, interconnected, and software-driven than ever. Unplanned breakdowns can halt production lines, delay shipments, disrupt energy distribution, or cause safety hazards. Downtime costs have surged across industries, making AI predictive insights critical for uninterrupted operations.

Need for Real-Time Visibility into Asset Health

Organizations want a live view of machine performance, stress levels, and degradation patterns. AI based predictive maintenance enables continuous monitoring using IoT sensors that measure temperature, vibration, acoustics, torque, pressure, and more. Real-time dashboards alert teams to issues before they escalate.

Impact on Profitability, Customer Experience, and Safety

A single unplanned failure can trigger product delays, missed SLAs, shipment penalties, customer dissatisfaction, or safety risks. AI predictive maintenance software reduces this risk and ensures consistent output quality and performance reliability.

Industries Relying Heavily on Predictive Intelligence

Artificial intelligence in predictive maintenance is now essential in:

- Manufacturing for robotics, CNC machines, and assembly lines

- Oil and gas for pumps, compressors, and pipelines

- Energy utilities for wind turbines, grids, transformers, and solar assets

- Transportation and logistics for fleets, aircraft engines, and rail systems

- Healthcare for imaging systems, lab instruments, and diagnostic machines

- Smart buildings for HVAC systems, elevators, and electrical units

These sectors operate high-value, mission-critical assets where even minor disruptions can create significant financial or operational impact. AI predictive maintenance provides the intelligence required to run these environments efficiently.

How AI Based Predictive Maintenance Works?

AI predictive maintenance solutions combine multiple advanced technologies to detect failure patterns, perform predictive diagnostics, and guide maintenance teams with data-driven actions.

Core Technologies Enabling AI Predictive Maintenance

Machine Learning Models

ML models identify anomaly patterns, detect abnormal machine behavior, and predict failures before they occur.

IoT Sensors

Sensors capture critical data such as vibration, temperature, rotation, noise, pressure, humidity, and electrical signatures. These real-time indicators help AI predictive algorithms assess equipment health continuously.

Big Data Analytics

AI prediction relies on processing millions of data points from historical logs, SCADA systems, IoT devices, and operational data lakes.

Cloud and Edge Computing

Cloud platforms scale predictive models across facilities, while edge computing ensures instant, low-latency analysis for sensitive environments.

Digital Twins

Virtual models simulate machine behavior, stress conditions, and life cycles to predict deterioration and optimize performance.

Data Flow Architecture for AI Predictive Maintenance

AI predictive maintenance software typically follows a multi-stage data pipeline:

Sensor Data Ingestion

IoT devices transmit data streams to edge nodes or cloud platforms.

Data Normalization and Feature Extraction

Raw signals are cleaned, structured, and converted into meaningful features for AI algorithms.

Model Training and Continuous Learning

AI models learn from operating patterns, label outcomes, and refine predictions through feedback loops.

Notifications, Alerts, and Automated Workflows

When anomalies are detected, the system generates alerts, assigns tasks, or triggers automated maintenance processes through CMMS or enterprise systems.

Unlock predictive intelligence for your assets. Partner with Experion to get started.

Key Benefits of AI Prediction

AI for predictive maintenance delivers measurable impact across equipment-heavy industries. By combining machine learning, IoT data, and real-time analytics, organizations gain a powerful ability to foresee failures, optimize maintenance schedules, reduce cost, and protect critical assets.

AI for predictive maintenance delivers measurable impact across equipment-heavy industries. By combining machine learning, IoT data, and real-time analytics, organizations gain a powerful ability to foresee failures, optimize maintenance schedules, reduce cost, and protect critical assets.

Below are the core benefits of adopting AI predictive maintenance software.

Reduced Unplanned Downtime

Unplanned downtime disrupts production, delays deliveries, impacts customer commitments, and increases labor costs. AI predictive maintenance detects early warning signs such as vibration spikes, thermal anomalies, and irregular acoustic patterns that humans may miss.

AI prediction models enable organizations to:

- Forecast failures days or weeks before breakdown

- Schedule repairs at optimal times

- Prevent cascading equipment damage

- Maintain production stability and performance

This shift from reactive firefighting to predictive planning is one of the biggest reasons industries are adopting AI-based predictive maintenance at scale.

Lower Maintenance Costs

AI predictive maintenance helps organizations move away from unnecessary routine servicing toward smarter, condition-based interventions.

Cost reductions come from:

- Fewer emergency repair calls

- Reduced overtime and labor waste

- Optimized spare parts usage

- Improved maintenance planning

- Lower machine failure risk

AI-powered predictive maintenance ensures that maintenance teams focus on the right tasks at the right time, which reduces overhead and eliminates wasteful spending.

Increased Equipment Lifespan

Artificial intelligence in predictive maintenance makes it possible to understand machine deterioration patterns and structural fatigue long before visual signs of wear appear.

AI predictive systems identify:

- Progressive degradation

- Hidden inconsistencies

- Micro-failures

- Load impact trends

This enables organizations to adopt targeted, preventive actions that slow down asset wear, significantly extending machine life.

Enhanced Safety and Compliance

Equipment failures can pose safety risks to workers or customers. AI predictive maintenance software acts as an intelligent watchdog, spotting safety-critical issues in advance.

Benefits include:

- Early detection of dangerous anomalies

- Automated compliance documentation

- Improved safety audit readiness

- Lower risk of workplace incidents

For industries like energy, transportation, logistics, and oil and gas, AI predictive maintenance helps meet strict regulatory requirements while protecting operations.

Higher Operational Efficiency

AI powered predictive maintenance simplifies decision-making and improves plant-wide visibility. Real-time dashboards allow teams to monitor asset health, track performance trends, and take action instantly.

Integration with ERP, EAM, and CMMS systems provides:

- Automated task assignment

- Optimized repair cycles

- Faster approvals

- Complete traceability

This results in streamlined workflows across maintenance operations.

AI Predictive Maintenance vs Traditional Maintenance Approaches

Maintenance strategies have evolved significantly, and the shift toward AI based predictive maintenance is reshaping operational models across industries.

Here is a breakdown of the three major approaches:

Reactive Maintenance

Fix equipment only after it breaks.

Characteristics:

- High downtime

- Unpredictable failures

- Expensive emergency repairs

Works for:

Non-critical, low-cost assets only.

Preventive Maintenance

Scheduled maintenance at fixed intervals regardless of actual machine health.

Characteristics:

- Often unnecessary servicing

- Higher labor and part replacement costs

- Still no guarantee of preventing failure

Works for:

Medium-value assets with stable degradation patterns.

AI Predictive Maintenance

Uses artificial intelligence to monitor real-time conditions and predict issues proactively.

Characteristics:

- Minimum downtime

- Maximum accuracy

- Optimal maintenance timing

- Resource and cost efficiency

Works for:

High-value, mission-critical assets that demand uninterrupted operations.

Comparison Table

| Maintenance Approach | Cost Efficiency | Downtime | Accuracy | Resource Usage |

| Reactive | Low | High | Low | High |

| Preventive | Medium | Medium | Medium | Medium |

| AI Predictive Maintenance | High | Very Low | High | Optimized |

AI predictive maintenance clearly surpasses traditional models by combining accuracy, efficiency, and automation.

Industry Applications of Artificial Intelligence in Predictive Maintenance

AI predictive maintenance software is transforming operations across diverse industries. Any sector that relies on machinery, fleets, or high-value assets benefits from predictive intelligence.

Below are the major applications across industries.

Manufacturing

Manufacturing uses AI for predictive maintenance to protect complex machinery such as:

- CNC machines

- Industrial robots

- Conveyor systems

- Compressors

- Motors and production lines

Benefits include reduced downtime, minimized production disruptions, and higher throughput.

Oil and Gas

AI in predictive maintenance supports:

- Pipeline corrosion monitoring

- Offshore drilling equipment

- Pumps and compressors

- Valve and flow monitoring systems

This improves safety, reduces environmental risks, and enhances operational continuity.

Energy and Utilities

AI based predictive maintenance strengthens reliability for power systems:

- Wind turbines

- Solar inverters

- Substation transformers

- Grid equipment

Predicting failure in advance helps avoid energy outages and service disruptions.

Transportation and Logistics

AI predictive maintenance helps fleet operators keep assets running smoothly:

- Trucks and delivery fleets

- Rail systems

- Aircraft engines

- Heavy shipping equipment

This enhances safety, delivery accuracy, and asset utilization.

Healthcare

AI powered predictive maintenance ensures reliability of critical medical systems:

- MRI and CT scanners

- X ray machines

- Laboratory analyzers

Preventing equipment downtime directly impacts patient care quality.

Smart Buildings and Facilities

Facilities use AI predictive maintenance for:

- HVAC systems

- Elevators and escalators

- Power distribution panels

This supports energy efficiency and a safer building environment.

Ready to build a future ready predictive maintenance strategy? Talk to Experion today.

Core Features of an Effective AI Predictive Maintenance System

AI predictive maintenance systems combine real-time monitoring, anomaly detection, machine learning insights, and seamless enterprise integration. For organizations evaluating predictive maintenance software, the following capabilities define a robust, scalable, and future-ready solution.

Real-Time Monitoring and Alerting

AI predictive systems continuously track asset conditions through IoT sensors that measure:

- Temperature

- Vibration

- Electrical currents

- Pressure

- Noise levels

- Humidity

This real-time monitoring enables early detection of anomalies and informs rapid decision-making.

Automated Diagnostics

AI based predictive maintenance automates root cause identification. Instead of manual troubleshooting, the software analyzes data patterns, identifies potential points of failure, and provides a probable cause map.

Automated diagnostics reduce inspection time and support quicker maintenance planning.

Root Cause Analysis

AI powered predictive maintenance systems understand not just what failed but why it is likely to fail. This helps maintenance engineers:

- Analyze recurring failures

- Identify deeper systemic issues

- Improve maintenance strategies

Root cause intelligence increases long-term asset reliability.

Predictive Scoring and Remaining Useful Life (RUL)

AI prediction models calculate health scores and estimate RUL for each asset. This allows teams to:

- Prioritize high-risk equipment

- Delay unnecessary maintenance

- Avoid sudden failures

Predictive scoring is central to AI in predictive maintenance.

Visualization Dashboards

AI predictive maintenance software includes interactive dashboards showing:

- Live machine status

- Failure probability graphs

- Trend analytics

- Maintenance recommendations

These dashboards improve collaboration across maintenance, operations, and engineering teams.

Integration with ERP, IoT Platforms, CMMS

AI predictive maintenance must integrate seamlessly with:

- ERP systems like SAP, Oracle, Microsoft Dynamics

- CMMS platforms for work orders

- IoT platforms such as AWS IoT, Azure IoT, Google Cloud IoT

- SCADA systems

Integration enables automated task assignments, asset histories, compliance tracking, and closed-loop workflows.

Scalability Across Fleets, Plants, or Locations

Enterprise-grade predictive maintenance must support:

- Thousands of sensors

- Multiple plants

- Distributed fleets

- Remote operations

Scalability is essential for organizations expanding production capacity or operating globally.

Step-by-Step Process to Implement AI Predictive Maintenance

Implementing AI predictive maintenance requires a systematic plan combining sensors, data engineering, machine learning, and enterprise integration.

Below is a clear, structured roadmap.

Step 1: Identify Critical Assets

Begin by selecting machines that:

- Cause the most downtime

- Have high maintenance costs

- Affect production output

- Require continuous operation

This ensures maximum ROI during early implementation.

Step 2: Install IoT Sensors

Sensors measure asset performance in real time. Common sensor types include:

- Vibration sensors for mechanical systems

- Thermal sensors for overheating detection

- Acoustic sensors for noise analysis

- Pressure sensors for hydraulic systems

- Electrical current sensors for motors and pumps

The right sensors create the foundation of AI based predictive maintenance.

Step 3: Centralize Data Collection

Companies must establish a secure, scalable data platform using:

- Cloud storage

- On-premise data lakes

- Edge computing devices

This ensures high-quality, continuous data flow for AI prediction.

Step 4: Build and Train Predictive Models

Data scientists build AI models that analyze:

- Operational patterns

- Failure signatures

- Stress indicators

- Degradation timelines

Models include:

- Anomaly detection

- Failure classification

- Remaining Useful Life (RUL) prediction

- Regression forecasts

This is the core of AI for predictive maintenance.

Step 5: Integrate with Existing Systems

AI predictive maintenance becomes powerful when integrated with enterprise systems such as:

- ERP

- CMMS

- SCADA

- IoT platforms

Integration automates work orders, maintenance schedules, and reporting.

Step 6: Pilot, Measure, Scale

Begin with one asset or a single production line.

Pilot results will show:

- Downtime reduction

- Accuracy of predictions

- Maintenance cost savings

- Operator acceptance

Once validated, scale the solution plant-wide or across global operations.

Challenges in Deploying AI-Driven Predictive Maintenance and Ways to Address Them

Implementing AI predictive maintenance can involve technical and organizational challenges. Understanding these early helps companies plan better.

- Data Quality Issues

Poor sensor data or incomplete historical data reduces AI accuracy.

Solution:

Introduce better sensors, consistent data collection practices, and automated cleaning pipelines.

- Lack of Skilled Personnel

AI, IoT, and data analytics require specialized skills not always available in-house.

Solution:

Partner with experienced AI predictive maintenance software providers or upskill teams with targeted training.

- Integration Complexity

Legacy machines may lack IoT connectivity or digital interfaces.

Solution:

Use retrofitted sensors, edge gateways, and modular integration layers.

- Model Drift and Continuous Optimization

AI models lose accuracy if machines age or conditions change.

Solution:

Enable continuous retraining and periodic validation procedures.

- Upfront Investment vs ROI Concerns

Organizations fear high initial costs.

Solution:

Show ROI through pilot programs, progressive scaling, and performance dashboards.

ROI of AI Predictive Maintenance Software

AI predictive maintenance creates strong and measurable ROI across industries. Companies typically experience financial returns within months.

Key ROI Drivers

- Reduction in unplanned downtime

- Increased equipment availability

- Reduced labor and maintenance expenses

- Optimized spare part inventory

- Minimized production loss

Typical ROI Timeline

Most medium to large enterprises see:

- 20 percent to 40 percent reduction in maintenance costs

- 30 percent to 50 percent reduction in downtime

- 2x to 10x ROI within the first year

AI predictive maintenance is not a cost but an investment with rapid and compounding returns.

Reduce downtime, cut costs, and boost reliability with AI predictive maintenance. Start now.

Future Trends in AI Predictive Maintenance

AI predictive maintenance continues to evolve rapidly as technologies mature, sensors become more intelligent, and enterprises adopt automation at scale. The next generation of AI prediction systems will reshape how industries manage assets and reliability.

Below are the top trends defining the future of AI predictive maintenance.

Self-Healing Machines

Equipment will soon be able to detect issues and automatically initiate corrective actions using robotics or closed-loop automation. AI powered predictive maintenance will not only diagnose problems but also trigger automated repairs, recalibration, or adjustments without human intervention.

Autonomous Maintenance Using Robotics

Robotic arms and mobile robots will perform:

- Physical inspections

- Lubrication

- Component replacement

- Cleaning

- Calibration

These capabilities will transform maintenance into an autonomous workflow supported by AI based predictive maintenance and automated decision-making.

Generative AI for Failure Interpretation

Generative AI models can analyze complex patterns and generate:

- Diagnostic reports

- Maintenance recommendations

- Technician instructions

- Failure narratives

This enhances the speed and accuracy of insights, especially for industries that require clear traceability and compliance.

5G-Enabled Edge AI

Predictive maintenance requires near real-time insights, especially for remote industrial sites, smart factories, fleets, and offshore systems.

5G combined with edge AI enables:

- Ultra-low latency monitoring

- Faster AI prediction

- High-frequency sensor sampling

- Improved data transfer reliability

This makes AI predictive maintenance software more responsive and effective.

Cross-Asset Intelligence for Multi-Location Facilities

AI predictive maintenance will unify data from global manufacturing plants, power stations, logistics fleets, and smart buildings to create:

- Centralized health dashboards

- Standardized maintenance rules

- Global anomaly models

This allows organizations to scale predictive maintenance efficiently across all their operations.

Build a smarter, safer, and more efficient maintenance ecosystem with Experion’s AI expertise.

Conclusion

AI predictive maintenance is transforming how industries manage equipment, reliability, and operational efficiency. Instead of reacting to failures or relying on fixed schedules, organizations can now use artificial intelligence in predictive maintenance to anticipate issues with precision, optimize resources, and maintain continuous operations.

Whether in manufacturing, logistics, oil and gas, smart facilities, or healthcare, AI powered predictive maintenance gives organizations the ability to operate with confidence, reduce costs, and improve safety. As machine learning models mature, IoT sensors become more advanced, and automation expands, predictive maintenance will evolve into an autonomous maintenance ecosystem supported by AI based predictive maintenance and intelligent workflows.

Organizations that embrace AI predictive solutions today position themselves at the forefront of efficiency, reliability, and competitive advantage. Experion brings deep engineering expertise, domain knowledge, and AI capabilities to help enterprises build scalable predictive maintenance software and future-ready reliability strategies.

Key Takeaways

- AI predictive maintenance enables early failure detection and reduces unplanned downtime.

- AI for predictive maintenance delivers higher accuracy than traditional preventive methods.

- Machine learning, IoT sensors, analytics, and edge computing drive predictive intelligence.

- AI predictive maintenance software improves safety, asset lifespan, and cost efficiency.

- Industries such as manufacturing, oil and gas, energy, logistics, healthcare, and smart buildings rely heavily on predictive insights.

- AI based predictive maintenance provides real-time monitoring, diagnostics, and root cause analysis.

- Continuous model training and integration with ERP, EAM, and CMMS systems are essential.

- ROI is strong, with many enterprises reducing downtime by up to 50 percent.

- Future trends include self-healing machinery, generative AI diagnostics, and autonomous maintenance systems.

- Experion supports enterprises in deploying scalable, AI powered predictive maintenance solutions tailored to operational needs.

FAQ’s

- What is AI predictive maintenance and how does it reduce equipment downtime?

It uses AI, IoT sensors, and machine learning to identify failures early, allowing planned repairs before breakdowns occur, reducing downtime significantly.

- How does AI predictive maintenance work compared to traditional preventive maintenance?

Predictive maintenance is condition-based and real time, unlike preventive maintenance which relies on fixed schedules.

- What are the business benefits of AI predictive maintenance systems?

Lower maintenance costs, improved reliability, longer asset lifespan, safer operations, and higher productivity.

- How much does AI predictive maintenance cost to implement?

Costs vary based on sensors, data infrastructure, model complexity, and number of assets, but ROI is typically fast.

- What data is required for AI predictive maintenance models?

Historical maintenance logs, sensor readings, operational data, environmental conditions, and usage patterns.

- How does AI detect machinery failures before they happen?

AI prediction algorithms analyze anomalies, compare patterns to failure signatures, and forecast deviations.

- Which industries benefit most from predictive maintenance?

Manufacturing, transportation, oil and gas, energy, logistics, healthcare, and utilities.

- How does AI predictive maintenance improve asset reliability in oil and gas?

It identifies corrosion, pressure anomalies, vibration faults, and equipment fatigue early.

- How is AI predictive maintenance helping energy companies prevent outages?

It monitors turbines, transformers, and grids in real time to detect faults before failures.

- How does predictive maintenance support fleet management?

AI tracks engine health, tire pressure, fuel systems, and operational stresses to prevent breakdowns.

- Can AI predictive maintenance reduce unplanned downtime in automotive plants?

Yes, it identifies faults in robotics, conveyors, and machining tools proactively.

- How do IoT sensors and AI work together in predictive maintenance?

Sensors provide data, AI analyzes it, and the system generates alerts or recommendations.

- How accurate are predictive maintenance algorithms compared to human inspections?

AI predictive maintenance is significantly more accurate due to continuous monitoring and large data analysis.

- How do you integrate predictive maintenance with ERP or CMMS systems?

Through APIs, middleware, and workflow integrations to automate maintenance tasks.

- What are common data challenges in implementing predictive maintenance?

Low-quality sensor data, missing logs, inconsistent formats, and insufficient labeling.

- How quickly can companies see ROI after adopting predictive maintenance?

Many companies see ROI within the first year, especially if downtime was previously high.

- Can AI predictive maintenance reduce operational and repair costs?

Yes, by optimizing service intervals, reducing spare part usage, and avoiding emergency repairs.

- Is predictive maintenance worth the investment for small businesses?

Yes, especially for small businesses with critical equipment where failure leads to revenue loss.